If you are a brake pad consumer, you may only care about how to replace brake pads. However, for a brake pad importer, distributor or buyer, they are more care about how the brake pads are manufactured and what the most important process for a brake pad is in manufacturing.

1, Raw friction material

Friction material is the most important for a brake pad. The different factories have their own formula.The formula determines the quality of the products. According to the classification, there are mainly 4 kinds of formulas. Metallic, semi-metallic, ceramic, NAO disc pad formula.

2, Steel back plate

In order to get a clean back plate without oil and rust, the back plate must be shot blasting before using. then apply glue on the steel back plate surface.

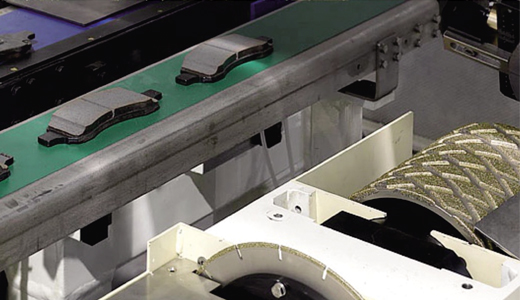

3, Hot press process

Forming friction materials into a brake pad. Adhering of backing plate with friction material by heat and pressure

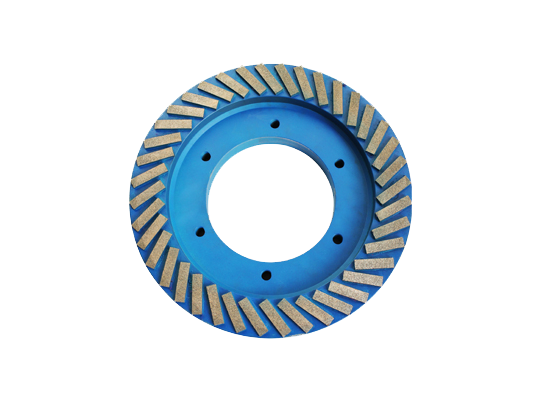

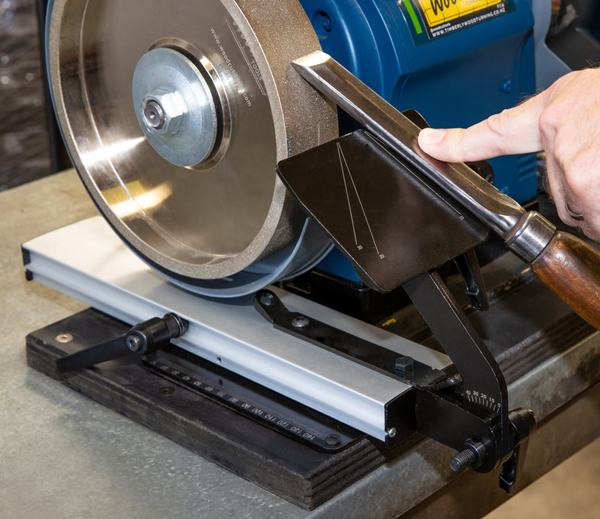

4, Curving

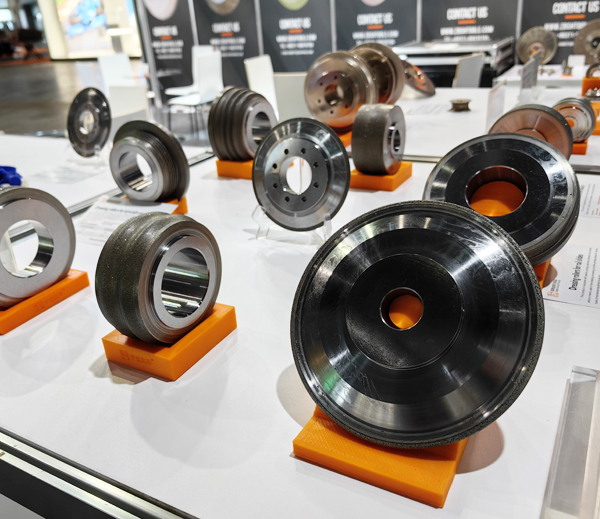

After curving, the formed friction material can reach an ideal brake performance. This is a key process. Therefore, Choosing the Brake pad Grinding Wheel is very important. Usually we choose electroplated diamond grinding wheels (

click here for more info about it), which is suitable for inner and outer arc grinding and surface grinding of disk brake pad in car and truck brake pads, which is low mental, half mental and ceramic formula etc.

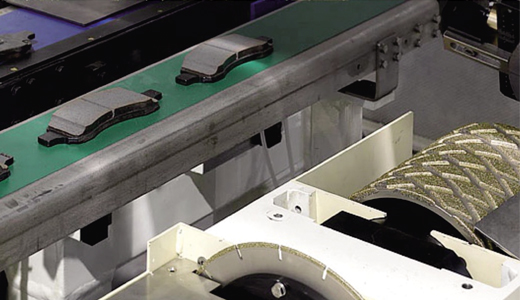

5, Grooving, slotting and chamfering on the brake pad.

To fit the disc brake rotors well. Reduce noise and improve dust. This is also a key process. Therefore, Choosing the Brake pad slotting, grooving, chamfering wheels is very important. Usually we choose electroplated diamond grooving, chamfering (

click here for more info about it), slotting wheels, which is suitable for chamfer grinding and grooving of disk brake pad in car and truck brake pads, which is low mental, half mental and ceramic formula etc.

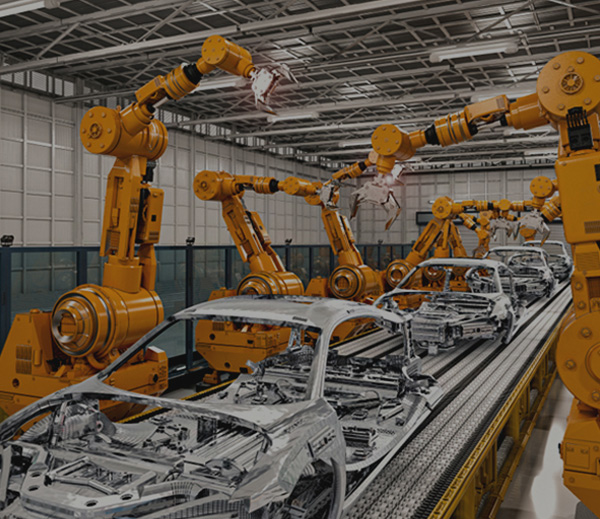

6, Painting

Spraying the powder on brake pad. Automatic painting production line.

7,Install Indicator

8,Disc brake pad installing

9, Shrinkage package.

The above is all the steps of the brake pad manufacturing process.

Zhongbang is one of the best diamond grinding wheel manufacturers and suppliers for brake pad for cars and trucks in China. If you are a foreign importer, distributor or buyer, and you want to find reliable brake pad manufacturers in China. Welcome to contact us at

melissa@zbshtools.com

.jpg)